AI empowers more precision for patient safety in minimal invasive surgery

As the popularity of minimally invasive surgery grows, Norwood Medical, a Heraeus Group company, is using AI to improve surgical precision and patient safety. Their cutting-edge AI integration improves component quality and ensures safer, more effective surgeries, revolutionizing patient care in the healthcare industry.

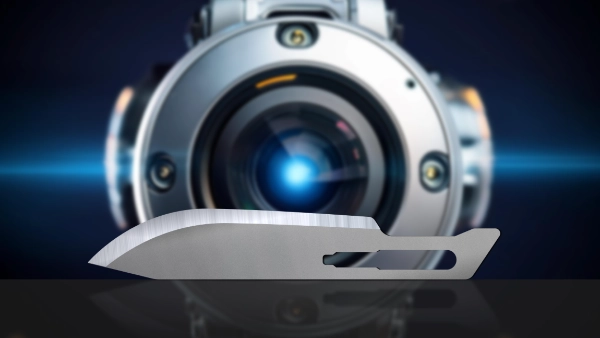

Globally, 310 million major surgeries are performed annually, with the USA and Europe accounting for 40 to 50 million and 20 million, respectively. As the world's population ages, the safety and quality of surgical care have become critical global health concerns. Norwood Medical, a key operating company of the Heraeus Group, is a leading manufacturer of precision medical device components, many of which play a crucial role in enabling Minimally Invasive Surgery (MIS). Through Artificial Intelligence (AI), the company has achieved the remarkable ability to detect damages in surgical blades as small as the tip of a ballpoint pen, ensuring unparalleled precision for patient safety within the MedTech industry.

The popularity of minimally invasive surgery (MIS) is rising due to its benefits like smaller incisions, faster recovery, reduced postoperative complications, and shorter hospital stays. Technological advancements in medical devices have improved the operability of MIS procedures, and the global demand for minimally invasive surgeries is expected to grow at a rate of 6.21% annually between 2023 and 2032.

Patient safety is a top priority, and harnessing cutting-edge technology to ensure it is essential. Heraeus has integrated AI across multiple facets of our organization, and it is a natural progression to apply this powerful tool to elevate precision in the healthcare industry. Each year, Norwood Medical manufactures about 6 million disposable surgical knives for MIS, covering a range of general surgery procedures. As pioneers in medical technology innovation, our expert team relentlessly pushes the boundaries of operation excellence. One of our key projects involves the introduction of an AI-based automated vision inspection machine.

Pioneer precision inspection with AI

In the high-stakes world of healthcare, where risks must be eradicated, the entire value chain is dedicated to ensuring precision and reliability. Traditionally, finished surgical blades undergo inspection using a microscope and physical examination. With an annual output of 6 million knives, this process results in tens of millions of inspections on blades with bare eyes that are half the size of the tip of a Type C plug head.

The project team initiated the improvement initiative by beginning with the linear cutter. Equipped with four cameras, the AI inspection machine meticulously examines each cutter from every angle. This automated process not only saves time and cost, but also significantly reduces the risks associated with manual handling, for example potential part damage and human visual error.

Leon Jones, Vice President of Controls & Automation at Norwood Medical, emphasized the collaborative nature of their work, stating, “Our client was involved from the very beginning, we worked together on this.” Describing it as a strong partnership, Jones remarked, “We started as early as in 2018, and were among the first to propose the use of AI. Our clients have embraced the idea and initiated the qualification process.” Following full approval of this innovative inspection process, the company is replicating its success across more production lines to surgical knife assemblies.

18,000 images for millimetre accuracy

A meticulous inspection of the linear surgical blade entails a thorough assessment for edge damage, cracks, thickness, and an array of imperfections, including stains, residues, excessive tool marks, and material deformation. 18,000 images were utilized to train the AI model, encompassing every conceivable imperfection on blades specified in millimetres. The more accurate the machine's detection, the less likely the blade is to malfunction during surgery, leading to increased precision in surgical operations.

The “human touch” behind the algorithms ensures the success of AI

Similar to surgeons who wield medical tools to heal, the success of this AI-powered visual inspection system is the result of dedicated human effort. “It initially began as a specialized software designed and programmed by our in-house engineers, with a sole focus on inspecting edge damages,” Jones explained. “Recognizing its potential, we expanded our collaboration to create a custom machine with a broader team. This comprehensive solution was implemented in partnership with the entire operational team and integration partners. With ongoing validation from the client throughout the process, the collaborative effort produced mutual benefits for all involved.”

The knives necessitate a 100% visual inspection for non-measurable defects. While the team is nearing completion of the AI models for all defect types, a ramp-up plan is already in place, with the anticipation of increased capacity.

A culture of innovation is deeply embedded within Heraeus, and this project is another great example of how AI is leveraged to enhance efficiency and, in this instance, to bolster precision for patient safety in MIS surgery. We anticipate further opportunities to refine our operations, ultimately benefiting a greater number of patients.